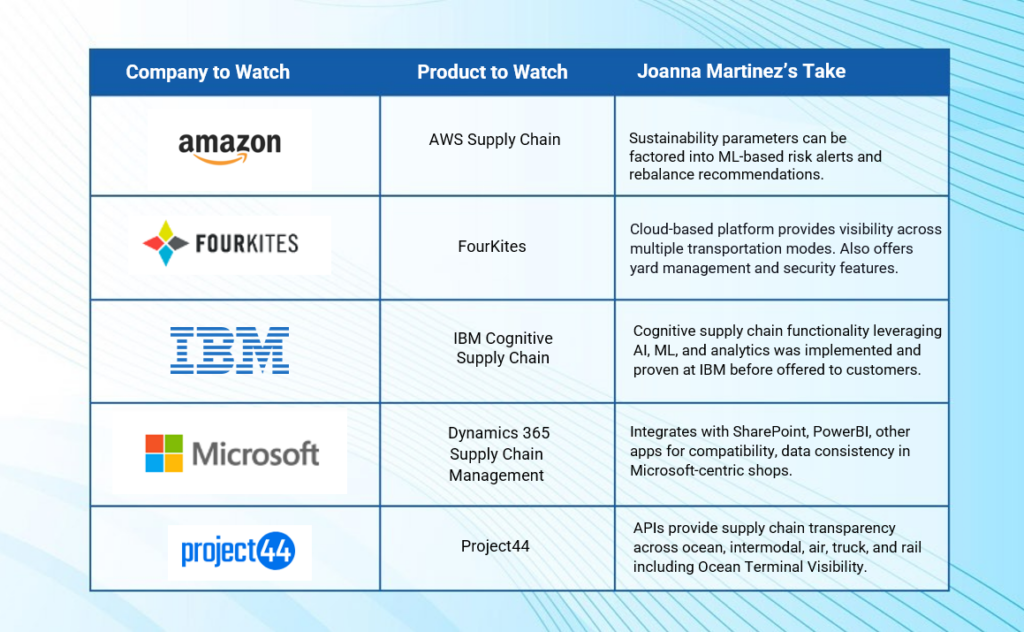

The supply chain market is a great place to be in 2024. Innovation is flowing from many sources and is no longer just the purview of startups. Large companies we’ve come to know well are also upping their innovation game, with a twist: They’re delivering products based on what they’ve made work within their own businesses.

Advances in artificial intelligence (AI) have allowed innovators to expand how they help supply chain teams. At first, supply chain technology focused on capturing inventory at various points in the supply chain. Now, machine learning (ML) and predictive analytics create a foundation for products that are capable of evaluating complex and less obvious inputs, creating more robust supply predictions, and recommending actions to avoid problems long before they occur.

Three of the companies detailed in this analysis are established firms with names we all recognize. But don’t write them off because they’ve been around for a while and you’re skeptical of their ability to innovate — the applications they offer are fresh and leverage the successes these firms have already achieved themselves in managing their own supply chains. While there is some overlap in what they offer, each has unique features as well.

Ask Cloud Wars AI Agent about this analysis

Then there are point solutions from much smaller companies with applications targeted at solving specific supply chain challenges. This analysis features two of them, both in the transportation arena. Before you can optimize inventory, you have to understand where it is in the first place, and that’s where they come in.

AWS Supply Chain

Amazon Web Services is selling a product that leverages the technology that it uses to manage its own business. AWS Supply Chain is a cloud-based application powered by ML. AWS Supply Chain provides a single source of truth by aggregating data across systems, speeding analysis, and reducing the likelihood that important information will be overlooked in making decisions.

AWS Supply Chain identifies stockout risks, the potential for excess stock, and lead-time deviations against the parameters that planners set. The data is displayed visually as a set of maps with color-coded graphics identifying risks in an easy-to-assess format. Then it makes ML-based re-balance recommendations with a collaboration feature to get the information out quickly to members of the team. Demand planners can spend their time taking action, not crunching numbers.

Sustainability parameters can be set to include the impacts of distance and CO2 Emissions in recommendations. So companies with a sustainability program can factor environmental impact into their rebalancing decisions.

This software is likely overkill for a company with a single location but is a no-brainer for businesses with many suppliers and warehouses such as:

- Manufacturers with multiple sites

- Retailers with multiple locations

- Businesses that must inventory perishable items like food or flowers

- Companies with few single-sourced incoming materials

- Companies that have made acquisitions and not yet integrated the acquired systems

FourKites

FourKites is a Real-Time Transportation Visibility Platform (RTTVP) and it occupies a spot in the Leader box of the Gartner Magic Quadrant for RTTVP. Like Project 44 (detailed below), FourKites provides cloud-based software for predictive, real-time visibility across all transportation modes. FourKites clients include over 1,200 of the world’s biggest brands including Coca-Cola, Pfizer, Dow, Best Buy, and Unilever.

The FourKites platform offers extended capabilities beyond transportation with a dynamic yard management system (YMS) and lane connect for “empty miles” collaboration. The company claims that this gives them the best end-to-end connected, multimodal visibility in the industry. Predictive analytics provides dynamic ETAs that have been measured to be more than six times more accurate than those from carriers themselves. A security feature is available in case goods being shipped are prone to theft, sensitive to altitude, or subject to temperature variability.

Choosing the best RTTVP depends on your specific business needs and requirements. If end-to-end visibility is your goal, FourKites could be a great choice.

Although FourKites emphasizes that it provides seamless integration into other core systems, your existing tech stack should influence your decision. When you’re considering logistics software, assess how it integrates with your systems, such as transportation management systems (TMS) and other supply chain software. If you are managing international operations, evaluate whether FourKites’ geographic reach is adequate for your needs.

IBM Supply Chain

During the pandemic, IBM managed to maintain a 100% order fulfillment rate to clients and reduce supply chain costs $160 million. How? By creating a cognitive supply chain, which leverages artificial intelligence (AI), ML, and data analytics to enhance decision-making processes within the supply chain. It goes beyond traditional supply chain management by incorporating advanced technologies to create a self-learning and self-improving system.

IBM’s supply chain group was assessing its processes and recognized that a lot of the talent it required was already under its own roof. In a separate division, there were significant efforts underway in AI, cloud computing, the Internet of Things (IoT), and other technologies. By leveraging this internal know-how, IBM garnered all the expertise it needed to redesign its supply chain. And by road-testing it internally, it proved it could work for a large-scale enterprise.

IBM started by consolidating legacy systems to a single source of information that virtually eliminated reliance on offline spreadsheets. That improved decision-making and helped identify inefficiencies, bottlenecks, and opportunities for improvement. Predictive analytics enables more accurate demand forecasting, leading to reduced overstock and stockouts. This, in turn, minimizes costs associated with excess inventory or lost sales. And the benefits keep coming, from transportation optimization to improved supplier collaboration.

By “walking the talk,” IBM is reinforcing its commitment to innovation and demonstrating to potential clients the immense potential for businesses to enhance their competitiveness and profitability.

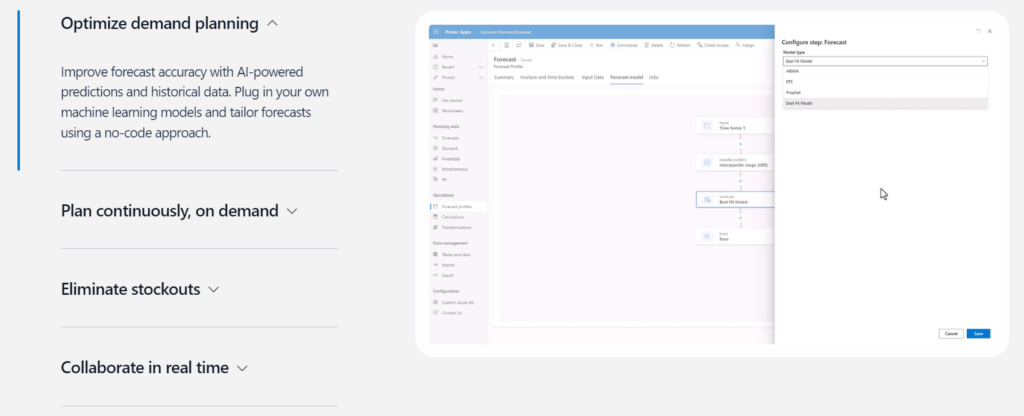

Microsoft Dynamics 365

Not every business manufactures a tangible good; those that don’t aren’t in need of warehouse and inventory optimization functionality. For such companies, the highly flexible Microsoft Dynamics 365, which not only provides supply chain and procurement functions but also supports sales, marketing, retail management, e-commerce, and other activities. In addition to aiding large enterprises, it contains an enterprise resource planning (ERP) module called Business Central aimed at small and medium-sized businesses. So there is both breadth and depth in its potential applications. Organizations can choose and implement the specific components that best meet their needs.

Dynamics 365 uses the Internet of Things (IoT) to connect factory equipment to production resources. The technology can measure downtime, quality, and delays, alerting managers to the impact that any disruption will have on supply plans. Beyond manufacturing environments, the procure-to-pay function uses AI to predict when vendors will pay their invoices. So too, AI/ ML supports the fraud protection module, helps identify automation opportunities, and enhances forecasts of many types.

Users who are already familiar with Microsoft software will likely find Dynamics 365’s user interface very intuitive, reducing the learning curve. Within a Microsoft-centric environment, Dynamics 365 integrates with other Microsoft products including Office 365, SharePoint, and Power BI. This can be a significant advantage for organizations that are heavily invested in the Microsoft ecosystem, as it promotes compatibility and data consistency.

Microsoft offers industry-specific solutions built on the Dynamics 365 platform, such as Dynamics 365 apps for retail, manufacturing, and healthcare. These industry-focused applications can provide a more tailored experience for organizations in those sectors.

Project44

When resources or funds are limited, sometimes the best solution is to laser-focus on the biggest pain point or bottleneck being encountered with a “point solution” like project44. Unlike other applications we’ve talked about in this analysis that are broad and cover many business functions, project44 targets a single area, namely, logistics.

project44, like FourKites, is an RTTVP. Traditionally, RTTVPs captured data on inventory moving to and from manufacturers, suppliers, and distributors via road transportation. project44’s goal is to comprehensively capture the entire transportation value chain including other methods beyond trucking, and eliminate gaps caused by lack of visibility into materials being transported. They do this by using APIs to connect various systems and facilitate seamless data flow.

In the end, this company is improving supply chain visibility across all modes of transportation including ocean freight, intermodal, air, truck, and rail. Trucking data is captured through integration with hundreds of devices on carriers across the globe.

project 44 also tracks 98+% of European and North American rail networks and is adding Asian rail to its coverage. Understanding that containers can drop from sight when they arrive at a port, project44 introduced an Ocean Terminal Visibility product to provide accurate data on the status and location of containers through the terminals.

The platform incorporates predictive analytics to forecast and identify potential disruptions or delays in the supply chain. Order-level visibility is provided, including estimated arrival times for each order. By leveraging data and analytics, the platform helps users identify trends, forecast demand, create insights to improve supply chain efficiency, and proactively address challenges before they escalate. The technology enables users to track the movement of freight in real time and make informed decisions promptly.

Project 44 is at the forefront of providing advanced visibility to the logistics and supply chain industry, leveraging technology to improve the tracking, management, and optimization of freight movements. They capture a piece of the supply chain that was previously missed.

Closing Thoughts

All five of these companies employ predictive analytics. All are cloud-based, and all are focused on getting real-time data and extracting value from that data quickly. Customers can choose one of the “big box” options from long-time leaders like IBM, or go for a point solution targeted on a specific problem.

Ultimately, the best supply chain software for your organization will depend on your specific business needs and requirements, as well as budgetary factors, but these all deserve a look.

More Analysis on Top Products for 2024: