SpecRight is part of a profile series featuring startups participating in the Innovation Path at Cloud Wars Expo, taking place June 28-30 in San Francisco.

Who They Are

Most product specifications — for the products themselves, their packaging, and other details — are managed in spreadsheets or legacy systems.

This results in data consistency and integrity challenges, access issues, and major efficiency problems. Without easy access to product and packaging data, employees aren’t able to make the quick, accurate decisions that are needed to remain competitive in the Acceleration Economy.

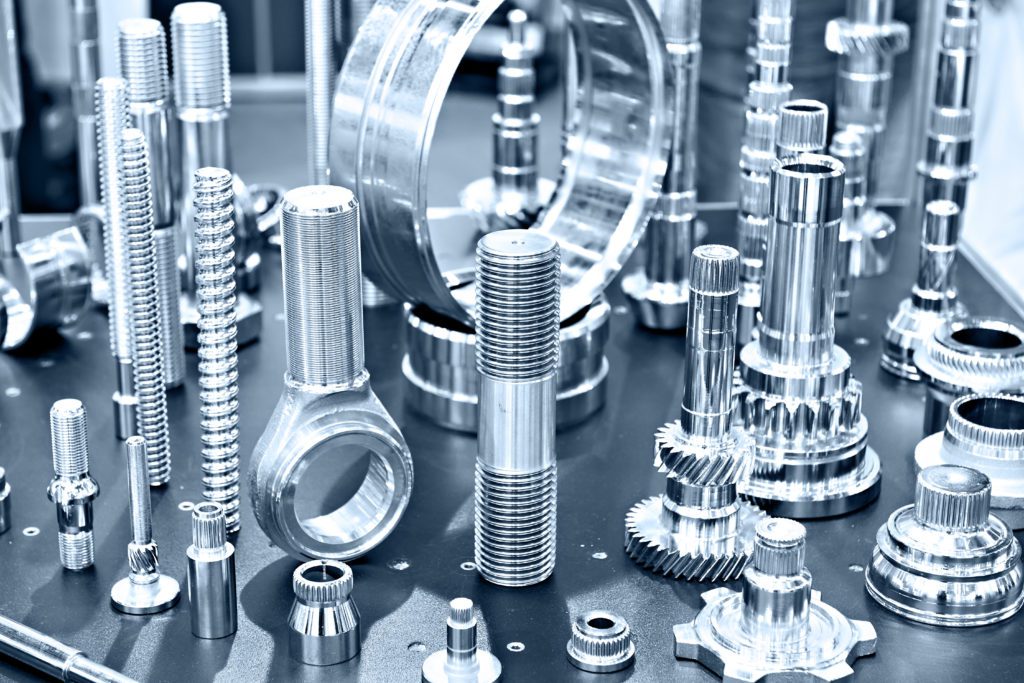

Those are the big issues that Specright took on with the launch of its company in 2015. “From automotive, to aerospace and food packaging, I saw that industries were struggling with inefficiencies that stemmed from a lack of packaging and product data,” says Specright CEO Matthew Wright. “I also realized any data that did exist was typically worthless because it lacked a common nomenclature. Not only was it frustrating, it was bad for business.”

The SpecRight platform is designed to digitize and manage all specification data, from raw materials to ingredients and formulas to packaging and finished goods. By digitizing and linking specifications together, companies create visibility and traceability across their supply chains. Today, more than one million products are in the Specright system, according to the company.

“From automotive, to aerospace and food packaging, I saw that industries were struggling with inefficiencies that stemmed from a lack of packaging and product data. I also realized any data that did exist was typically worthless because it lacked a common nomenclature.”

Matthew Wright, Founder and CEO of Specright

Based in Tustin, California, the company has 120 employees. It has $44.8 million in venture capital funding, and it’s part of the SAP.io accelerator program. The two primary customers, or organizations, that Specright serves today are supply chain and operations, says Mike Anderson, Vice President of Digital Transformation and Sales Operations at Specright.

What They Do

SpecRight’s primary product is its specification management system, with modules that add functionality on top of that. Here’s a more detailed look at the platform and modules:

Specification Management

Specright’s approach is built on the premise that everything should start at the DNA level of products and packaging. It’s not enough to simply digitize specifications; they have to be mapped and interconnected to drive intelligence. Once specifications have been digitized and mapped in a single repository, it’s easier to layer on correct workflows, approvals, and processes.

A slew of functions are managed by the company’s platform, including:

- Raw materials management

- Formula and ingredients management

- Packaging management

- Sub-assemblies

- Labels and artwork management

- Document management

- Bill of materials management

- Machinery and facilities management

From its inception, Specright aimed to solve the problem of companies putting up with an “acceptable” level of waste that resulted from not getting the specification data right upfront, Anderson says. “If you get the spec right on the front end, you can drive a lot of efficiencies downstream,” he says. “Create less waste, better margins through better processes. This is a vehicle to reduce waste that companies produce.”

Quality Management

The specification-first approach to quality builds traceability and prevents issues before they occur. With digitized specs shared across a network (departments, suppliers, co-manufacturers), customers can quickly cut down or eliminate issues related to outdated specs. The software can ingest data from production and suppliers to provide a 360-degree view of products for real-time insights. Root-cause analysis reveals what happened when things go wrong.

These quality management functions enable supply chain traceability, audits, and greater collaboration between suppliers.

Supplier Management

Suppliers can access digital, up-to-date specifications controlled by the brand, so there are no duplicative (or inconsistent) specs across suppliers. All data is available in real-time, so suppliers can have confidence that they’ve got the latest version of specs. Using the supplier collaboration portal, suppliers and vendors gain a clear understanding of a brand’s direct materials needs, so both suppliers and vendors can optimize their execution process to meet those needs.

These measures prevent suppliers from producing out-of-spec products or having packaging requirements lost in communication. By having everyone share a single source of truth, customers can gain increased visibility, improve supplier performance, and have confidence the correct products are being made. “This ensures that suppliers meet the specs, have access to the latest specs so the whole supply chain is working off the same page,” Anderson says. “Rather than ‘this supplier has this version of the spec, and another supplier has a different version’.”

New Product Development

This module enables collaboration, data capture, and approvals between research and development and other departments to facilitate new product development processes that build from a spec, rather than starting at a finished good and trying to break down from there, Anderson says. “It’s a fundamentally new approach to how products are thought of.”

Sustainability Solutions

One of the biggest problems in sustainability today is a lack of visibility. All too often, companies set goals without knowing exactly where they stand today as a baseline. Specright is helping companies shift from being reactive to proactive and turning their sustainability goals into measurable actions.

Specright has numerous features aimed at helping customers maximize and manage sustainability initiatives:

- The Specright recommendations engine can proactively scan specifications and deliver insights on how to make products and packaging more sustainable.

- Over 50 templates help customers understand what data needs to be captured to report on sustainability efforts.

- Pre-configured reports and dashboards deliver real-time sustainability metrics to help customers understand the sustainability of their current products.

Specright Network

Companies can publish their specs for partners to access on the Specright Network. Their specifications are stored as immutable records. By enabling cryptography as part of the Specright platform, the company maintains that it’s able to take collaboration to the next level: Users can quickly publish, change, and update specifications across companies and parties in the supply chain while retaining strong security controls.

ISTA PackSight

The International Safe Transit Association (ISTA), is a trusted authority in predictive package-performance testing. Specright partnered with ISTA to create PackSight. Built on top of Specright’s platform, PackSight enables packaging and supply chain professionals to select, collect, and analyze ISTA tests online. Rigorous testing ensures the protection of a package’s contents as it moves through the global distribution environment.

Who They’ve Impacted

Specright’s technology is used in food and beverage, beauty and cosmetics, consumer packaged goods, and retail industries.

One such customer is Central Garden & Pet, a 40-plus-year-old owner of top consumer and professional brands for lawns, gardens, and pets.

The company has 28 business units, over 100 brands, and disparate data sets, documentation, and processes when sharing data sets between departments and suppliers. The company is using Specright to digitize information for packaging, formulas, manufacturing specs, regulatory requirements, product inspections, corrective actions, and supplier assessment.

Key benefits of Specright for Central Garden & Pet, according to Director of Quality Paul Gray, include:

- Inspection reporting that used to take 4-6 hours is available instantly inside of dashboards.

- If an ingredient or formula change is required, all linked product and specification records are updated simultaneously,

- Pulling a spec before might takes days (after connecting with procurement, quality, operations, and engineering) and now takes about 15 seconds. They have confidence the spec is correct because it’s stored in the SpecRight system.

The Future and Final Thoughts

Specright’s direction and product strategy highlight a major data management, access, and consistency problem within and across companies. I suspect many of us — even those who aren’t supply chain professionals — can relate to the challenges. Imagine how much greater these challenges are when they span a complex network of companies!

I will be eager to see the ‘network effect’ of Specright’s technology over time, to monitor how broadly it gets deployed, and the extent to which suppliers use it jointly and collaboratively to help all of their businesses run more efficiently. “Where we see the end state or next steps in the process, is to have a customer running Specright and suppliers as well,” Anderson says.

Given the challenges facing today’s supply chains, Specright presents a solid value proposition to help businesses get a better handle on their product data and work with partners to optimize their supply chains.

Want to gain more insights from Cloud Wars Expo?

Starting on July 20th, more than 40 hours of on-demand cloud education content will be available for free to Acceleration Economy Subscribers.