Cogniac is part of a profile series featuring startups participating in the Innovation Path at Cloud Wars Expo, taking place June 28-30 in San Francisco.

Who They Are:

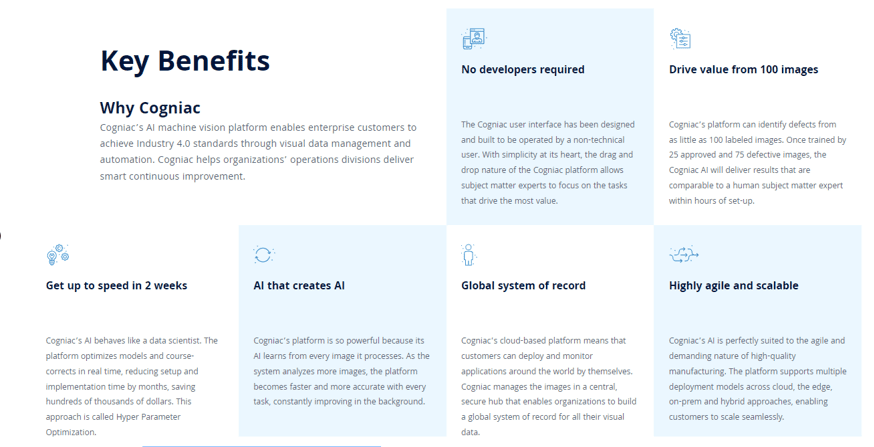

Cogniac is the industry leader in AI-powered computer vision technology. Its software platform is built from the ground up for performance and ease of real-world deployment. Cogniac’s platform combines artificial intelligence (AI) models, cloud computing, and big data management to capture images of visible items. Then, it uses those images to effect continuous improvement in areas such as detecting and eliminating defects.

The company’s vision is to “redefine human performance, productivity, and efficiency by maximizing the value of visual data.”

Computer vision is a form of AI that allows machines to categorize and differentiate between images. It can identify and classify objects and then react to what it “sees.”

Based in San Jose, California, the company’s CEO is Chuck Myers, who holds patents in wireless technology, automotive, and facial recognition. The company has $40 million in venture capital funding and has been part of the SAP.io startup accelerator program for roughly two years.

“Cogniac’s software platform offers extensive solutions across a variety of verticals,” said Vahan Tchakerian, Chief Partnership Officer at Cogniac. “Through our partnership with SAP, businesses that use SAP solutions will now have access to Cogniac’s technology. By offering our platform on the SAP Store, we are able to scale more efficiently and deliver exceptional performance in the manufacturing and industrial sectors”.

The company has an impressive roster of customers across industries and use cases that impact core business functions and drive major quality improvements, cost savings, and reduced waste, to name just a few benefits.

What They Do:

Cogniac’s core product ingests images from a wide variety of sources — still, video, infrared, thermal, X-ray, and more (it is camera-agnostic) — in factory floors, shipping containers, logistics warehouses, or other settings.

It can train the system using AI with as few as 100 images (25 that are approved and 75 that show defective materials). Once it has scrutinized those 100 images, it can identify defects and deliver results that are consistent with human analysis. The platform improves continuously, with every image ingested. The company says its AI engine can reach 99% accuracy in a matter of days. One critical benefit, of course, is freeing humans to perform more work that only humans can do.

AI workflows — to inspect and detect defects, for example — are built using an interactive and intuitive user experience. This is an important consideration: It means no developers are required. Availability and prioritization of developer resources can be a barrier to deploying AI technology, so the company’s approach takes that issue off the table.

The Cogniac system integrates into customers’ Manufacturing Resource Planning Systems. It delivers real-time predictions and provides analytics regarding core functions.

The system also provides full data management to store imagery, model predictions, and consensus history. The company’s system processes over 50 million images every month, across three continents, and in 10 industries. Those data points give a clear indication of the enterprise-scale of the company’s technology, and the mission-critical customer use cases it supports.

Here’s one real-world example of the Cogniac system at work, in the automotive industry:

Working with 28 high-resolution cameras, Cogniac detects splits, tears, and other defects on each door opening panel. Each defective part is flagged to the human supervisor, who double-checks the query. A part that is confirmed to be defective is then removed from the production line and reworked, recycled, or scrapped.

Cogniac enables the system to identify new types of defects to the part, constantly learning and becoming more intelligent. In some instances, Cogniac can even predict certain issues with parts that have not yet been proven defective.

Cogniac customers have flexible deployment options for its system: They can do so in the cloud, on-premises, or in a hybrid model that leverages the cloud and on-premises servers.

Who They’ve Impacted

As noted previously, Cogniac’s AI-powered Computer Vision system is being used to support enterprise-scale, strategic applications. One great example is Doosan Bobcat, which uses the system for kitting inspection. Headquartered in West Fargo, North Dakota, Doosan Bobcat is a global manufacturer of construction, agriculture, landscaping, and grounds maintenance equipment, attachments, and services

To create one kit for a machine typically requires 30 small crates. On a typical day, 40,000 to 45,000 parts are picked for these crates. That scale makes it virtually impossible for a person to pick and inspect accurately the first time, or every time. In the past, the accuracy ratio was roughly 1 in 3; in other words, two-thirds of all kits were shipped inaccurately. One can easily imagine the time lost in that process and the costs incurred.

“The Cogniac system provides significant benefits for us, leading to higher efficiencies and optimized quality control in our processes.”

Russ Honeyman, Vice President of Quality Management at Doosan Bobcat North America

Doosan Bobcat successfully implemented Cogniac across its kitting operations based on several factors: trainability of the system, speed to deploy, and Cogniac’s ease of integration into existing systems.

Since deploying Cogniac, 12 to 15 mis-picks are being identified in a typical shift. The error rate has decreased to 1 in 20,000. Doosan Bobcat says its kit accuracy is now 99.995%.

“Cogniac has produced a world-class technology platform. Given our long history of innovation and focus on technology at Bobcat, the Cogniac system provides significant benefits for us, leading to higher efficiencies and optimized quality control in our processes,” says Russ Honeyman, vice president of quality management at Doosan Bobcat North America.

The Future and Closing Thoughts:

One unique aspect of Cogniac is that, despite its age and startup status, the company has deep representation across industries, enterprise customers, and core, strategic business applications. That’s because its technology has an immediate, tangible impact (better quality, reduced costs) on the bottom- and top-line business results.

So, it will be compelling to track where the company evolves and expands. We’ll continue to track this innovator, its technology, and its customer use cases.