Verusen is part of a profile series featuring startups participating in the Innovation Path at Cloud Wars Expo, taking place June 28-30 in San Francisco.

Who They Are

Verusen is unlike a lot of tech startups, in that its founder isn’t a serial entrepreneur who starts and sells companies, and he’s not a recent grad school alum looking to change the world.

Instead, Paul Noble’s vision for his company and its product was born of his real-world experiences dealing with supply chain challenges at Sherwin-Williams, specifically issues that existed in sharing data between manufacturers and suppliers.

“I wanted to solve the problem of why can’t a user, its suppliers, and the suppliers of its suppliers get on the same page and exchange data more effectively so the supply chain can work more collaboratively,” Noble says, noting that the problem remains a big one today, as evidenced by the last two-plus-years worth of supply chain malfunctions that have become so prominent. “I saw how that handcuffed each part in the supply chain, and that was the genesis of our solution.”

Verusen makes materials management software that uses artificial intelligence (AI) and natural language processing (NLP) to let organizations manage and govern their materials more effectively, with the goal of helping customers harmonize disparate data so they have what they need, when they need it, where they need. It calls that concept “Material Truth.”

The company, based in Atlanta, has $39 million in venture capital funding, 66 employees, big-name customers, and is a member of the SAP.io startup accelerator program.

What They Do

Verusen works with:

- Manufacturers to optimize the way they manage inventory and collaborate with suppliers

- CPG firms to better respond to the changing mix of products that customers buy

- Energy and oil/gas firms to ensure reliability and availability of their materials

- Pulp and paper to build resiliency and transparency into supply chains

Today, roughly 80% of the company’s customer base uses SAP systems including ERP. Their customers are also users of Oracle and Infor ERP technology.

Officials note that one major advantage of Verusen’s software is the use of natural language processing (NLP), which allows the software to dramatically compress the normally time-consuming process of cleansing, categorizing, and governing data for analysis. Noble said that other systems can take 9-18 months to manage that process (which should give a clear sense of the scale of that data), while Verusen’s system typically does it in 3 months.

To illustrate the complexity the Verusen system aims to rein in, Noble noted that a single, widely used motor might be represented in a thousand different ways across various companies — or even business units of the same company — in the supply chain. So, being able to communicate, share data, and effectively manage materials in this type of environment can be a monumental challenge.

“I wanted to solve the problem of why can’t a user, its suppliers, and the suppliers of its suppliers get on the same page and exchange data more effectively so the supply chain can work more collaboratively. I saw how that handcuffed each part in the supply chain, and that was the genesis of our solution.”

Paul Noble, Verusen CEO

“Based on our ability to understand that all these things are really one, or are interchangeable, then we can make much more informed recommendations on what you should inventory, where you should inventory it, what you should buy, and who you should buy from.”

Verusen’s platform has four primary applications:

Trusted Material

This is the core application that performs inventory optimization and data harmonization. It combines AI and ML with human intelligence to enable material optimization. It can conduct global materials searches across systems and locations.

It brings order to what Noble refers to as the “Frankenstein” of systems that companies maintain. Customers need to get data for all the materials that their companies use and how those materials have been moved and acted upon over the last several years. “This is where we combine data in systems with deep learning and present it to an expert,” Noble explains.

Trusted Network

This application supports multi-echelon materials management for network-wide inventory and materials optimization functions. It’s intended to ensure customers have optimal visibility into working capital. (A multi-echelon supply chain includes complex networks with many distribution points from origin to the end customer.)

This functionality allows suppliers to work together to understand what customers need in individual facilities versus what they have. “You can really take control of what the entire organization needs, so you can lower your capital number without introducing more risk,” Noble explains.

Trusted Supply

This application’s objective is to create strategic supplier alignment through visibility into demand signals within a company’s supply network. When a supplier onboards a new customer and gets insight into their material requirements and usage, they can work together to drive greater operational efficiency and take steps such as locating materials closer to customers.

Dashboards

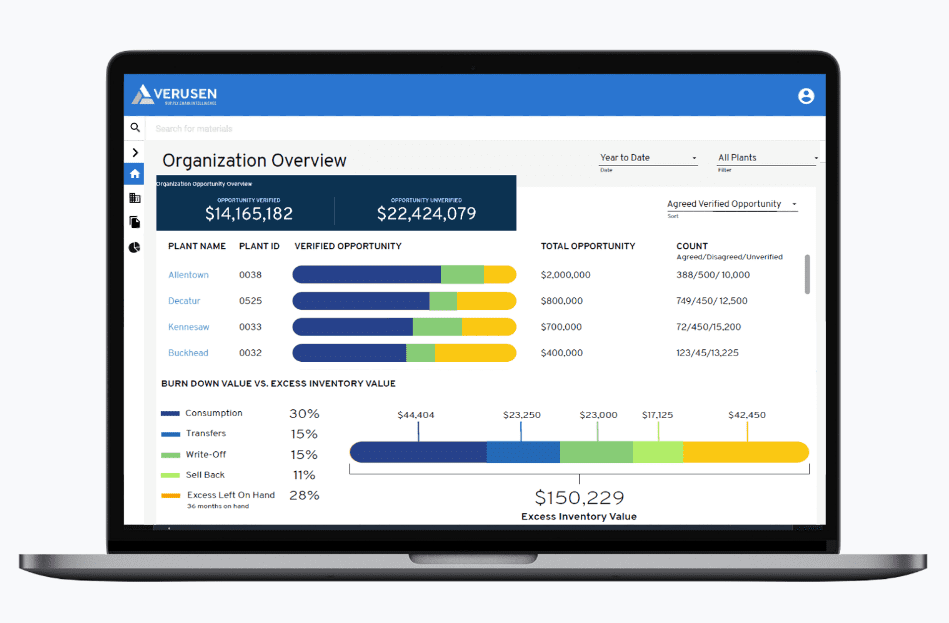

Dashboards are a standard functionality in most SaaS and supply chain applications. Verusen’s focus is to deliver predictive insights and even recommendations through its dashboards.

In Verusen’s case, its dashboards can function as scorecards in large organizations that have hundreds or potentially thousands of users. They can pinpoint plant-level opportunities or more granular material-level opportunities. They can identify opportunities to drive down capital expenses and save money.

Who They’ve Impacted

A Fortune 500 manufacturer has worked with Verusen to find overlap and redundancies in purchasing as well as conduct risk management assessments.

The company, not identified by name, but a maker of paperboard and paper-based packaging for beverage, food service, and other companies, has over 70 facilities worldwide. 50% of its spare part purchases were managed through blanket purchase orders with no material number. As a result, it was buying redundant parts.

By applying Verusen AI technology, the company identified working capital cost savings within 30 days, eliminated duplicate purchases, and reduced spending. More specifically, the Verusen customer:

- Identified over $100 million in savings opportunities in less than 45 days

- Verified savings opportunities of $26 million in less than 30 days

- Achieved working capital reduction of $40 million in less than 12 months

The Future

Verusen has a compelling opportunity to extend the reach of its materials management and supply chain software beyond the four walls of any given company, which is how the software has been primarily deployed to date. One can easily see the implications of being able to add greater visibility and data consistency between partners in a supply chain, bringing cost controls and capital management to achieve a network effect, rather than just benefits within a company.

Indeed, that is part of the company’s product roadmap. “There are some collaborative things we’re doing across customers and suppliers, users, and suppliers. This year we’re building out that full experience and putting resources toward automating signals” between partners, Noble says. “It’s not quite there yet in the platform, but it’s in process.”

That could be welcome news to a high number of acutely challenged businesses whose supply chains have been disrupted — and ineffective — over the last two-plus years.

Closing Thoughts

Verusen is attacking a problem that is literally massive — and global — in scale. It’s not lacking in ambition, looking to capture and utilize demand signals across a supply chain and its partners to make today’s supply chains work more effectively. We can all relate to the impact of those supply chain issues. So, here’s hoping that big companies that are struggling under the weight of their supply chains see opportunity to tap technology to help their business run better and serve their customers better. That would be a win for Verusen, its customers, and the buyers of its customers’ products.