Over the last eighteen months, the surge in generative AI’s capabilities, exemplified by tools like ChatGPT and Microsoft Copilot, has expanded the bounds of professional productivity. Yet, this surge is just a prelude to a more radical shift looming on the horizon: the emergence of autonomous agents.

As the chief information officer (CIO) of a manufacturing company, I’m interested in how these autonomous agents could revolutionize how we produce goods. In this analysis, I’ll dissect the evolution from AI as a supplementary tool to an autonomous agent and analyze how it could reshape the very fabric of the manufacturing industry.

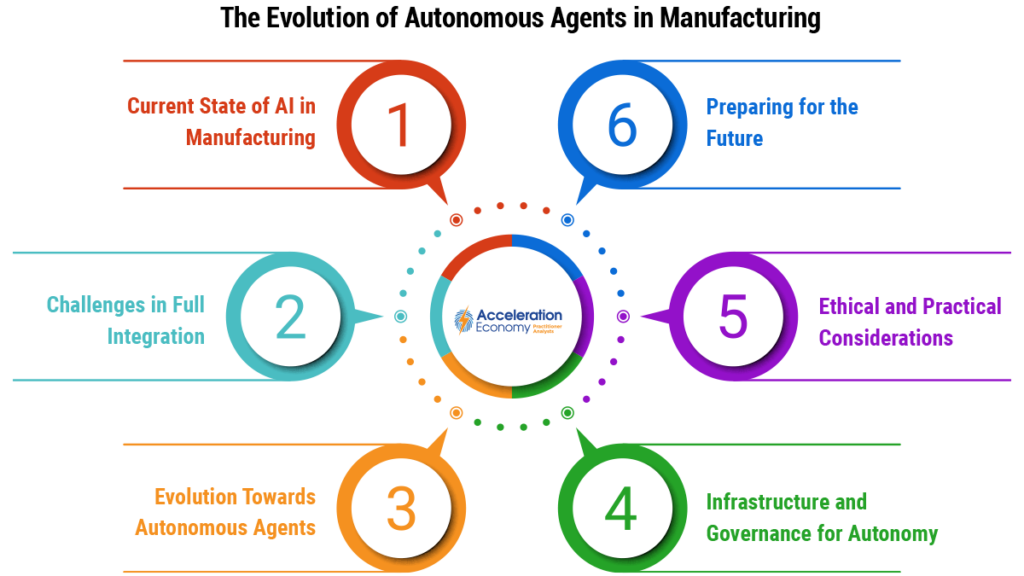

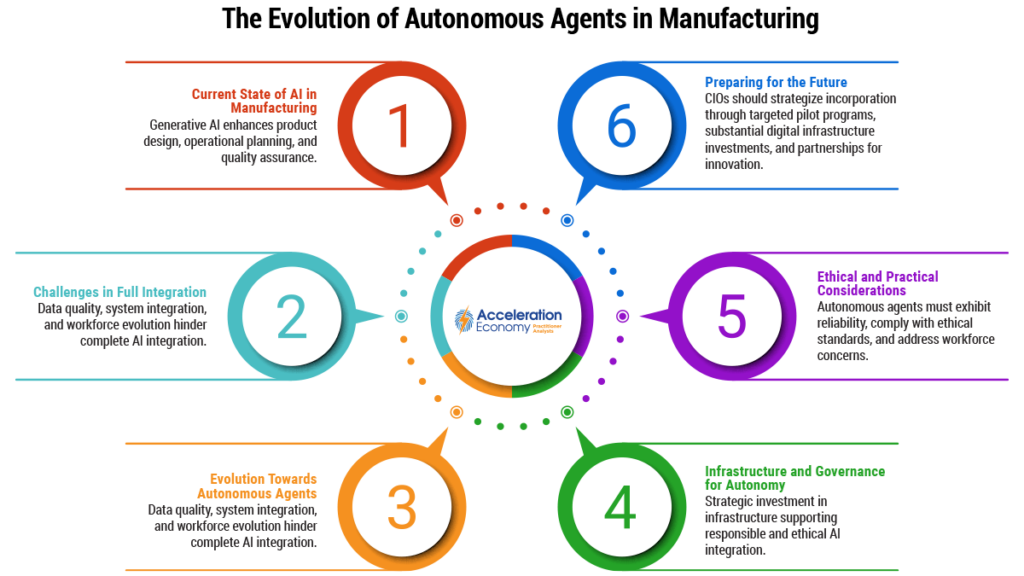

The Current State of AI in Manufacturing

Generative AI’s integration into manufacturing has yielded significant enhancements in product design, operational planning, and execution. AI-driven design tools can now generate a vast array of product configurations tailored to optimize costs, material efficiency, and environmental impact. This capability transforms planning processes, as AI’s predictive analytics allow decision-makers to visualize potential production outcomes and adapt strategies accordingly. The human-AI partnership is also crucial for quality assurance, where AI algorithms excel in detecting defects faster than the human eye, leaving humans to make the final call on borderline cases.

Despite these strides, challenges like data quality, system integration, and grasping the nuances of complex manufacturing scenarios hamper AI’s full integration into manufacturing. Melding AI into established systems requires considerable investment and a depth of expertise. The financial outlay, although significant, can be rationalized by the long-term return on investment (ROI). Equally vital is addressing the workforce evolution, as employees need to be retrained to thrive in a workplace increasingly augmented by intelligent machines.

Ask Cloud Wars AI Agent about this analysis

The Evolution Towards Autonomous Agents

The transformation from AI as an assistive technology to an autonomous agent represents a quantum leap in manufacturing. Autonomous agents are poised to transition from passive entities awaiting instructions to dynamic systems orchestrating entire production segments, from sourcing raw materials to steering the final stages of delivery.

These agents will assume complex tasks such as recalibrating production schedules in response to supply chain volatility, managing energy consumption for peak efficiency, and conducting vendor negotiations independently. Achieving such a high level of autonomy requires AI to be capable of interpreting intricate data from multiple sources, making decisions amid uncertainty, and learning from its actions to refine its performance continuously.

To welcome this technological renaissance, manufacturers must strategically invest in infrastructure and governance models that promote responsible and ethical AI use and create an ecosystem that supports continuous learning and adaptability.

Ethical and Practical Considerations

The ascent of autonomous agents in manufacturing brings to the forefront significant ethical and practical considerations. Practically, autonomous agent deployment requires systems that have unparalleled reliability and engender trust. Within the precision-driven realm of manufacturing, where safety is paramount, these agents must function within tightly regulated parameters and exhibit a flawless operational record.

AI agents’ decisions in manufacturing settings must mirror human values and comply with ethical standards. These agents need to demonstrate effectiveness in their tasks while also upholding ethical and social responsibility. The workforce’s transformation, spurred by the rise of AI agents, calls for a proactive approach to managing concerns such as job displacement and the redefinition of roles.

With this increase in autonomy, stringent governance is required to maintain accountability for AI’s actions. Manufacturers will need to create governance structures to address liability, compliance with evolving regulations, and ongoing AI system maintenance. As AI agents grow in independence, the nature of human-AI interaction will shift toward oversight and strategic direction, allowing humans to harness the efficiency of AI while guiding it with moral judgment and strategic insight.

Preparing for the Future

As a CIO peering into the horizon of AI’s advancements, strategizing for a future autonomous agents is as crucial as understanding the underlying technology. A methodical approach, beginning with targeted pilot programs, will allow for a thorough assessment of the benefits and risks associated with autonomous agents before a broader rollout.

To facilitate these sophisticated AI systems, substantial investments in digital infrastructure, encompassing data management systems, network architecture, and security protocols, are essential. Moreover, ensuring the workforce is equipped to interact with and manage these advanced AI systems requires a commitment to ongoing training and development.

Partnerships with tech providers, research institutions, and other manufacturers will be invaluable in fostering a culture of innovation and collective growth, enabling a shared journey toward realizing the potential of autonomous agents.

Conclusion

The integration of autonomous agents into manufacturing demands astute strategic planning, robust investment, workforce development, governance, and risk management. Industry leaders must adopt a proactive and thoughtful approach to navigate the potential challenges and capitalize on the transformative opportunities that AI presents. The future where autonomous agents are a central feature of manufacturing is within reach, and it is incumbent upon business leaders to guide this evolution responsibly, ensuring technology amplifies human potential and drives innovation.