You’ve got 90 days to modernize and digitalize a portfolio of 300 non-residential buildings across the globe so that all safety, security, and environmental operations can be optimized via remote control and autonomous management.

Should you:

- a) take a 3-month vacation;

- b) equip all facilities personnel with pagers and fax machines; or

- c) call Honeywell?

As the digital economy takes shape and pace of change in all facets of our lives increases, Honeywell is leveraging its 114 years of industrial and process-control expertise into what it intends to make the world’s premiere industrial-software company.

Positioning itself as the “ERP system for industrial operations,” Honeywell has created and is rapidly expanding its very own software and digital-expertise factory called Honeywell Forge.

That software company—a mix of industrial platform and operational data architecture—is the core component within the parent company’s even more-expansive Honeywell Connected Enterprise initiative launched by CEO Darius Admaczyk and led by tech veteran Que Dallara, who serves as president and CEO.

The Honeywell Forge and Connected Enterprise are so vital to the company’s next 114 years that Adamczyk has referred to them as “the #1 strategic priority for Honeywell.”

The chief product officer for Honeywell Forge, former Oracle executive David Trice, is leading this mother of all digital-transformation initiatives. In a recent interview, Trice said the opportunity to drive new levels of value and intelligence for industrial companies is enormous.

“Whether you’re talking about manufacturing plants, warehouses, maintenance facilities, or other types of non-residential buildings, the people in charge of them are faced with vast numbers of assets, operating models, and processes that were never intended to work together, let alone intelligently and harmoniously,” Trice said.

“So the result is they’ve got hundreds of silos—not just data silos but operating silos and process silos and equipment silos—plus hundreds of data models that are all completely fragmented.”

(To gain more insight into the Honeywell Forge strategy and capabilities, please check out our full video interview with Trice in this episode of the Cloud Wars Live podcast.)

And all that disconnectedness has surged to the surface here in 2020 as the COVID-induced economic slowdown has led many industrial companies to clamp down aggressively on costs, particularly operating expenses, Trice said.

“Honeywell Forge’s customers are being told to cut operating expenses, cut the people costs associated with facilities, cut their CapEx, and essentially figure out how to do more with less.”

Focusing on customer requirements is deeply wired within Trice, who before joining Honeywell was a CRM executive at Oracle after it acquired a CRM startup he had founded. While at Oracle, Trice was involved in the buildout of Oracle’s cloud CRM and CX strategy, which Honeywell said was a big factor in its decision to bring him aboard to lead the Honeywell cloud initiative.

To meet those customer demands, Trice’s Honeywell enterprise-software team is evangelizing a strategy of lean and autonomous: using digital solutions to create data-driven operating models that not only reduce costs but increase productivity and, ultimately, enhance the experiences of building occupants.

That involves an infusion of some classic enterprise-software capabilities into the operations of industrial companies that until recently were much more focused on operational technology (OT) than on information technology (IT).

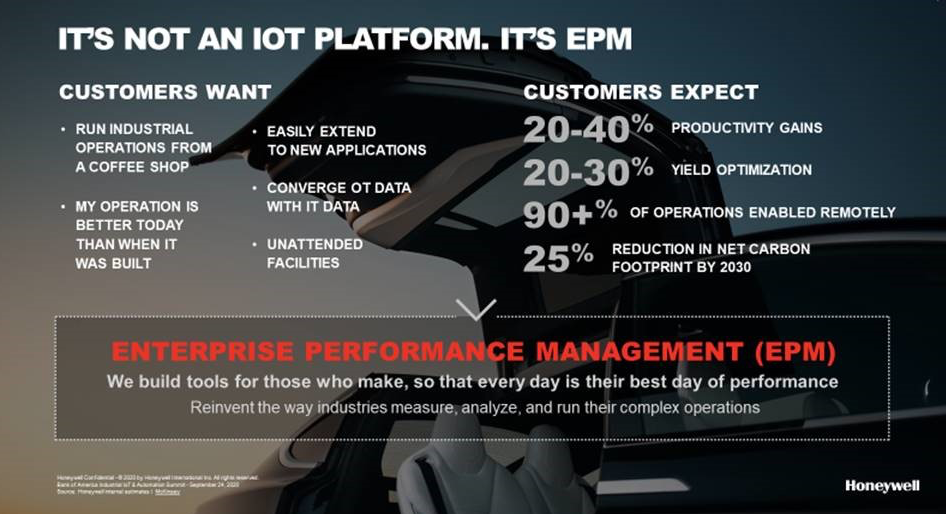

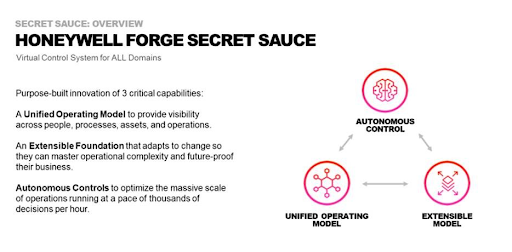

And to weave together the formerly disparate worlds of OT and IT, Honeywell Forge—harkening back with its name to the heavy-industry roots of its parent—is deploying its suite of Enterprise Performance Management software solutions. Calling Honeywell EPM “the Tesla of industrials,” Trice outlined 3 key elements to that orchestration strategy:

- the creation and ongoing execution of a unified operating model;

- the creation of extensibility for new solutions and capabilities that customers will inevitably want and need to add over time; and

- the fusion of those efforts into the customers’ larger digital-transformation initiatives.

“One of the things that makes the Honeywell Forge approach unique is our aggressive push for autonomous operations wherever possible,” Trice said, citing heating, cooling, safety, elevators, contactless operations, and other systems.

“The only way these industrial customers can meet their goals and objectives is if they can virtualize their operations and their control systems. That’s what Honeywell’s done for them in the physical world for the past century, and now we’re taking all that expertise and knowledge and leveraging it into the digital world as well.”

To achieve changes of that scale, Honeywell has had to undergo its own radical transformation. In October of 2018, Adamczyk launched Honeywell Connected Enterprise as the digital engine to greatly accelerate the evolution into not just a company that writes some software but rather one that views the world and behaves like a software company.

One year later, that hyperevolution had reached the point where 63% of all Honeywell engineers are software engineers, far overshadowing its legacy engineering-skills base from the fields of mechanical, electrical and chemical engineers.

And 3 months ago, on the strength of its new vision to become a powerhouse in Industrial IoT, data, digital, and the cloud, Honeywell was readmitted to the Dow Jones Industrial Average. So we’ve got a 114-year-old software startup springing out of an industrial company with a 100-year history as a publicly traded company.

For Trice, all of that current innovation linked with all of that history of achievement and expertise presents a powerful opportunity.

“We have customers telling us today, ‘Not only do I want to be lean, but I want to be autonomous as well. And that’s a real glimpse into the future,” Trice said.

“I’ve spent countless hours with senior executives of our customers around the world, and not once did I hear somebody say, ‘I’ve got an IoT problem.’

“Not once did I hear somebody say, ‘I’ve got to be running on somebody’s cloud.’ Instead, it always comes back to these core bottom-line realities: ‘I need to do more with less. I need to save money. And I need to have a leaner operation that I run on behalf of my customers and my shareholders.’ ”

It’s hard to imagine how long it might take a traditional startup software company to understand those types of challenges and problems, particularly in today’s incredibly fast-paced and high-change world. But Trice believes that Honeywell Forge, drawing on its parent’s 114 years of very hard-earned expertise, relationships and trust, can do what no other software can do.

“With Honeywell Forge Enterprise Performance Management, we’re trying to suggest that the way of running your operation tomorrow will be fundamentally different,” Trice said.

“That future will be digital, it will run autonomously, and you’ll be able run it remotely so you can control it from anywhere.

“That’s where the world is headed, and we expect to lead the way within Honeywell to ensure that we can successfully lead our customers on that journey as well.”

This article brought to you by Honeywell.