The purpose of Job Scheduling is to schedule individual production orders so that each operation in the production route has a start date/time and end date/time. Job Scheduling also works to ensure that the materials that are needed for production are available when the operation starts.

The role of Capacity Planning is to assess whether there is enough time, resources, and capabilities to finish production in time to meet demand.

When set up correctly, Job Scheduling and Capacity Planning work together to plan a production schedule to the most efficient extent. This blog will highlight the import setups required to make the most out of the Job Scheduling and Capacity Planning features in Dynamics 365 for Supply Chain Management.

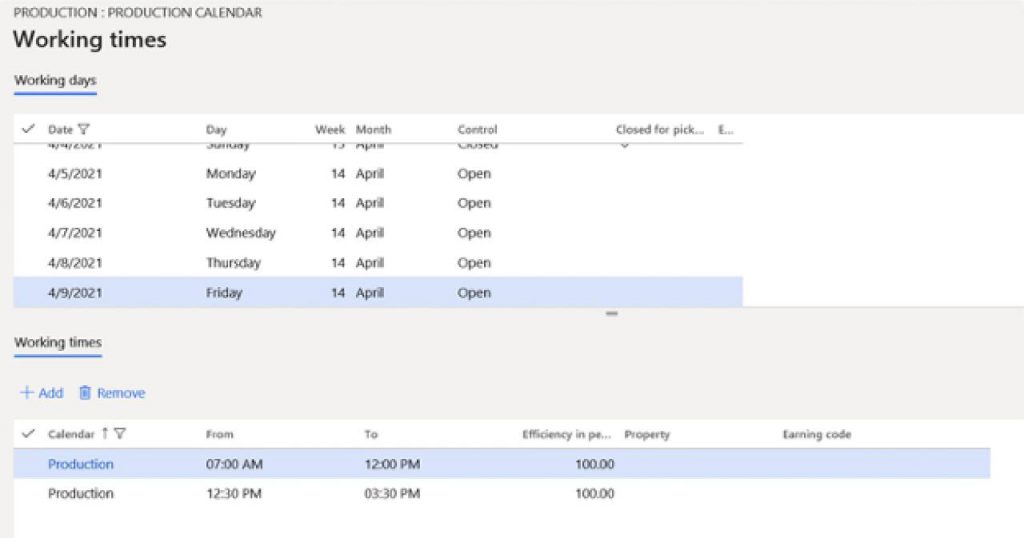

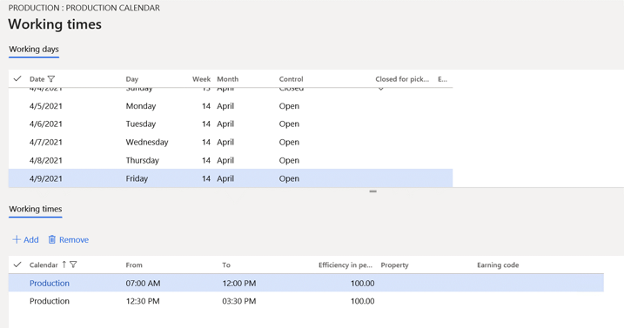

Calendars

Calendars determine when and how long resources and/or resource groups are available. In a calendar, you specify the specific working days and times. Calendars are very flexible, for instance, you can block out weekends, holidays, and lunch breaks. This way, when you run job scheduling, the system will only schedule jobs within the appropriate working days/times of the calendar. You can create multiple calendars and assign different calendars to different resources.

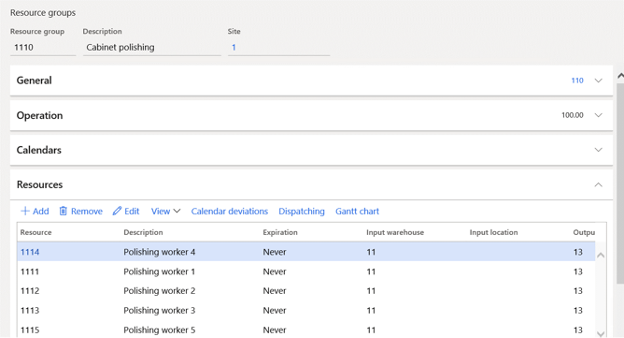

Resource Groups

A resource group represents a group of resources that are interchangeable during scheduling. Resource groups are great when you have multiple resources that can perform the same operations or when you have operations that require more than one resource. In that case, you can assign a resource group to a routing operation and have the system assign an individual resource, or multiple, within that group when job scheduling is run.

Resources

Resources are reserved for a specific operation during job scheduling. Resources can represent a worker or group of workers, a machine, tool, location, or more. Within a resource, you can specify the resource’s operations scheduling percentage, efficiency percentage, capabilities, capacity, resource group, and calendar. You can also assign a priority to a capability. This means that if two resources have the same capability, the resource with the higher priority will be reserved for job scheduling

Running Job Scheduling

After you have created your production orders. You can run job scheduling to schedule operations based on operation resource requirements. Each operation on a production route has its own resource requirements. An operation can require a specific resource, resource group, capability, skill, or a combination of requirements.

From that point, there are a variety of scheduling parameters to select. For instance:

From that point, there are a variety of scheduling parameters to select. For instance:

- Scheduling direction – Can be forward scheduling meaning production will start as early as possible or backward scheduling meaning production will start as late as possible and still meet its target deadline.

- Primary resource selection – The system will choose resources based on duration (which resource can complete the operation the soonest) or priority (a resource with the highest priority is selected)

- Finite capacity – Select this check box if you want the job scheduling to include capacity limits. This means the load on the resource will not be greater than the capacity of the resource

- Finite material – Select this check box if you want the job scheduling to consider materials as finite. If the materials are finite, the coverage of material for that time is considered.

Gantt Chart

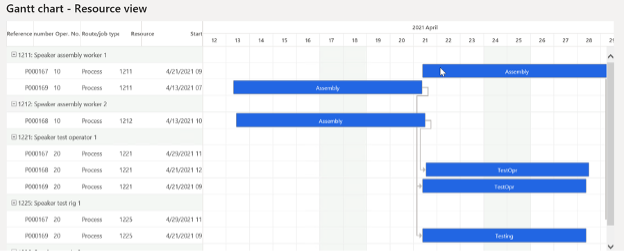

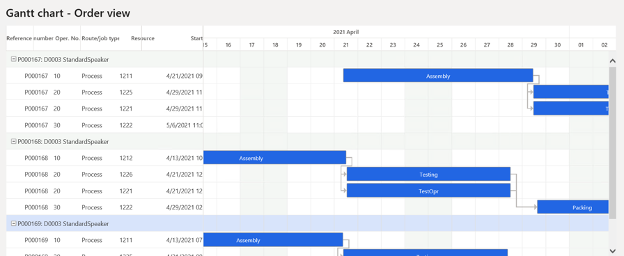

Visualize your production schedule with the Gantt chart. You have the ability to view your production schedule by resource or order. You can move operations to new dates and move them between resources. Any changes you make in the Gantt chart update the route on the production order.

Gantt chart – Resource view

Gantt chart – Resource view

Gantt chart – Order view

Next Steps

If you are interested in learning more about job scheduling as well as maximizing the use of Microsoft Dynamics 365 for Finance and Supply Chain Management contact us here to find out how we can help you grow your business. You can also email us at info@loganconsulting.com or call (312) 345-8817.