When you hear the word “manufacturing” what do you think of? Massive assembly lines? Robotic arms swinging around with parts or welding capabilities? However, there is so much more to manufacturing than these rudimentary ideas. Yes, these are still needed, but for most, we take this industry for granted.

Look around your home or business; anything you can physically touch was built, created, stitched, or assembled somewhere in the world. We often overlook the huge effort to get something in our hands. But, the innovations happening in this space are truly amazing. Many technology companies are co-creating with customers to deliver accelerated, tangible outcomes.

How are these tech companies tackling the manufacturing challenges of supply chain, logistics, inventory management, IoT, plant management, real-time insights, and more? Answering this question is the central focus for Day 3 of the Industry Cloud Battleground Week.

Microsoft on Manufacturing

Out of the gate, Microsoft recognized the huge disruption the pandemic has caused for manufacturers, supply chains, logistics, and more. However, in spite of this, many are embracing digital transformation. Further, 62% of manufacturers are forging ahead with their smart manufacturing investments and these are increasing by an estimated 20% this year alone.

On top of this, there is an explosion of data. Microsoft is seeing some smart factories that generate a petabyte of data per day. Yet, sadly, these companies are not even using 1% of their data, let alone extracting any real value from it.

So, what is Microsoft doing to address the global challenges manufacturing companies are facing?

- They are listening to customers. In a research study Microsoft conducted, they discovered that 85% of manufacturers believe production ecosystems are important to the future competitiveness of their businesses.

- Collaboration is critical. Microsoft Teams enabled engineers to monitor factories and equipment for installation and troubleshooting.

- Start with a modular framework. This activates end-to-end cloud services for supply chain visibility, edge services for securely connecting factory devices, and adding intelligence at both the edge and in the cloud.

- Equip customers with purpose-built technology. The Microsoft Cloud for Manufacturing is leveraging machine learning to deliver cognitive and predictive anomaly detection, predictive maintenance, and proactive services in our asset productivity and always-on service capabilities.

Salesforce on Manufacturing

Three core areas of manufacturing were detailed by Salesforce. The first was the supply chain. Commercial operations are trying to get the right information about product forecasts and demand for operations to meet the expectations of customers. Second, partners are looking for easier and faster access to product pricing and rebate information. For context, 98% of manufacturing companies believe that the right reward and recognition programs for partners give them a competitive edge. Third, service for customer assets and products had to be done in a new way such as remote monitoring and support.

What direction did Salesforce take to provide solutions for these core areas?

- Understand the customer. The Salesforce Customer 360 platform gives organizations full capabilities for sales, marketing, service, integration, analytics, and more. Additionally, a complete of the customer is surfaced to drive decision-making at all levels.

- Cross-team engagement. The combination of the Salesforce platform and Slack gives customers, partners, suppliers, and others a way to orchestrate communication.

- Harmonize disparate systems. Chargeurs has 29 offices around the world with multiple manufacturing and innovation centers. The collaboration with Salesforce provided the customizable and flexible functionality they needed to succeed.

- Deliver industry-specific capabilities. The Salesforce Manufacturing Cloud coupled with 20+ years of experience empowers customers with necessary functionality. This solution is built on top of Customer 360 to be scalable and extensible for supply chain management, product lifecycle management, and more. Further, Tableau supplies insights, powered by artificial intelligence, on accounts, pricing, performance, product recommendations, and more.

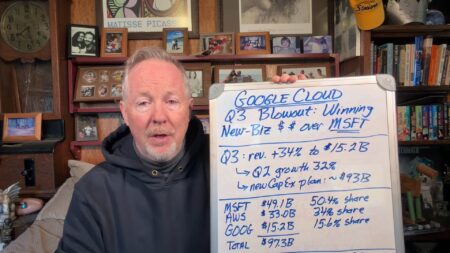

Google Cloud on Manufacturing

The buying decisions made by customers greatly impact the supply and demand for manufacturers. For instance, Foxfire discovered that 95% of new car buyers are coming through Google. With this in mind, Google is improving upon these experiences along the entire customer journey from discovery to purchase to ownership.

Google customers expect a high level of quality in the output of data. One example is a leading semiconductor equipment maker, ASML. Its customers rely on the equipment to be extremely precise, even down to the atomic level. Further, ASML was able to shorten its learning cycle from months of research and development to weeks.

How does Google Cloud fit into the manufacturing ecosystem?

- Model and predict outcomes. Through the use of AutoML Vision the factory floor is getting an upgrade. Production quality control comes with significant underlying costs upwards of 15 to 20% of sales revenue. Foxconn utilized AutoML Vision to reduce the defect escape rate to 10% while also reducing the time needed to inspect every single component to 0.3 seconds.

- Make Industry 4.0 use cases work. One well-established automaker is using Google Cloud to connect 2,500+ machines across 22 sites. Now, 3 out of 4 being made are running through the Google system.

- Realize environmental impact. This same automaker had a goal to reduce energy consumption dramatically. Surprisingly, more than 30% of energy was being consumed in the paint shop. Through the use of AI, they reduced the amount of energy used in the painting process.

- Reimagine the digital twin. Data pulled from three different areas helped one manufacturing company streamline the entire supply chain and spot potential disruptions in the supply chain or inventory levels.

Oracle on Manufacturing

Human capital is more than just buzzwords for Oracle. They represent the most valuable resource within any manufacturing company and the potential acceleration of innovation. Building on the innovation mindset is the inventive ways IoT surfaces data which drives the real-time decisions that need to be made within the plant.

Additionally, the Oracle cloud infrastructure brings together the back-office applications and the front office applications. This enables customers to plan and execute using quickly with the assistance of AI and IoT.

Where is Oracle focusing its attention to help large-scale manufacturers?

- Smart manufacturing ecosystems. The reliance on machinery is of the utmost importance and any downtime is costly brings production to a halt. Oracle’s Smart Manufacturing solution brings together shop floor data, IoT devices, maintenance systems, and planning systems infused with AI/ML to contextualize information for actionable insights.

- Provide remote visibility. One customer automated their inventory for finished products on the plant lot. Further, lot surveillance was simplified. Instead of someone driving around in a golf cart, they actually use a drone with a video camera. The data captured is used to help manage costly materials in the manufacturing process.

- Collaborating and innovating with customers. Red Bull Racing Honda is using high-performance computing to create a digital twin of racing simulations that provide data for multiple different or how a driver might react to different circumstances.

SAP on Manufacturing

The relationships that SAP has built with its customers are amazing. They work with customers daily in councils, meetings, and individual situations to learn from them what’s important. These relationships brought five major things to the forefront which are customer centricity, serving the segment, making products digital, manufacturing the products, and strategic priority. Each of these areas requires the end customer to be considered from and micro and macro level, and then build things as efficiently as possible.

SAP realizes that an outcome-based economy is the new business model that customers are pursuing in their quest to serve customers better. This begs the question: How is SAP helping customers achieve their goals in this quest?

- Everything as a service. The product portfolio that SAP brings helps businesses from the initial stages of the sales process all the way through to the final purchasing choices made by customers.

- Equip the edge. Digital manufacturing requires organizations to consider where processes are run from on-premises models, hybrid models, multi-cloud models, and delivering computing power to endpoint devices.

- Manage potential risk. The intense monitoring and real-time data needed all rely on a resilient network. Companies really want to reduce risk in their networks or the potential exposure to risk. This means understanding every single node and protecting the infrastructure from any security or downtime failures.

- Support sustainability efforts. Currently, there are immense pressures being placed on manufacturing companies to reduce their emissions footprint. SAP provides customers with the ability to manage material and value flow and now provides ways to manage CO2 emissions.

Industry Cloud Battleground Week: Available On-Demand

Sponsored by Salesforce, Google Cloud, Oracle, Microsoft, SAP, and Workday, this 5-day digital event delivered insights to inspire, educate and engage business and technology leaders who are actively defining their industry-specific cloud strategy.